At the Origins of quality

The art of nature is pure magic

At the Origins of quality

The art of nature is pure magic

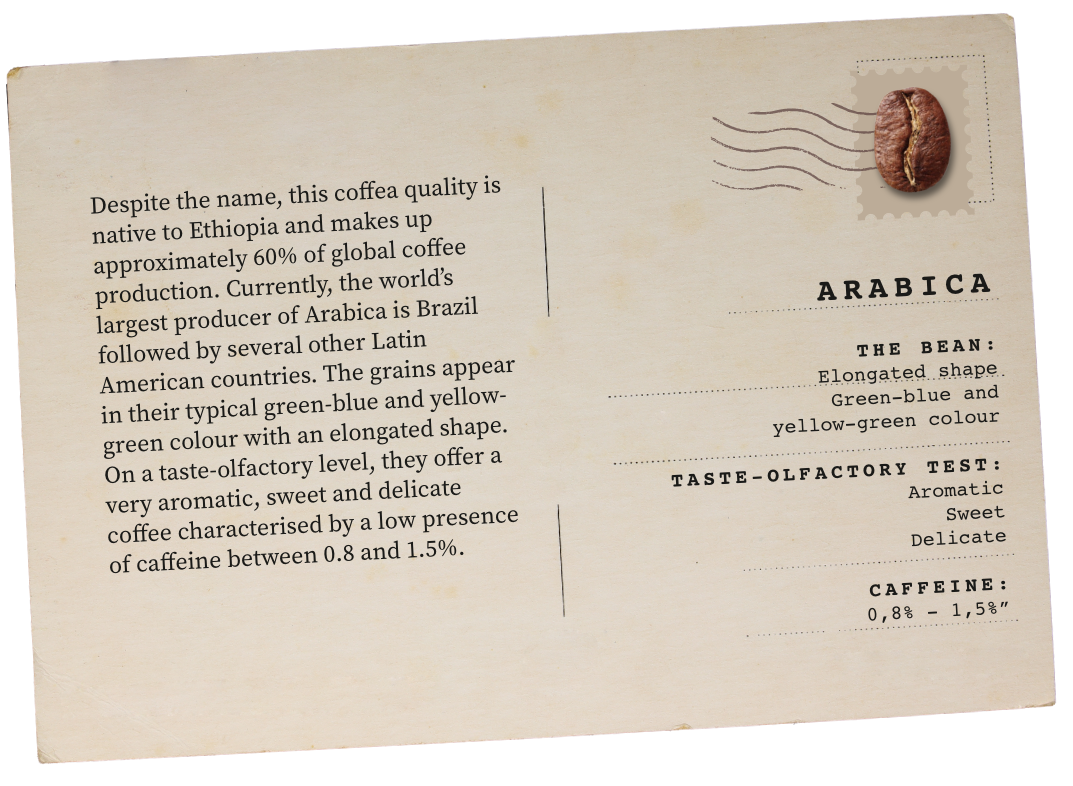

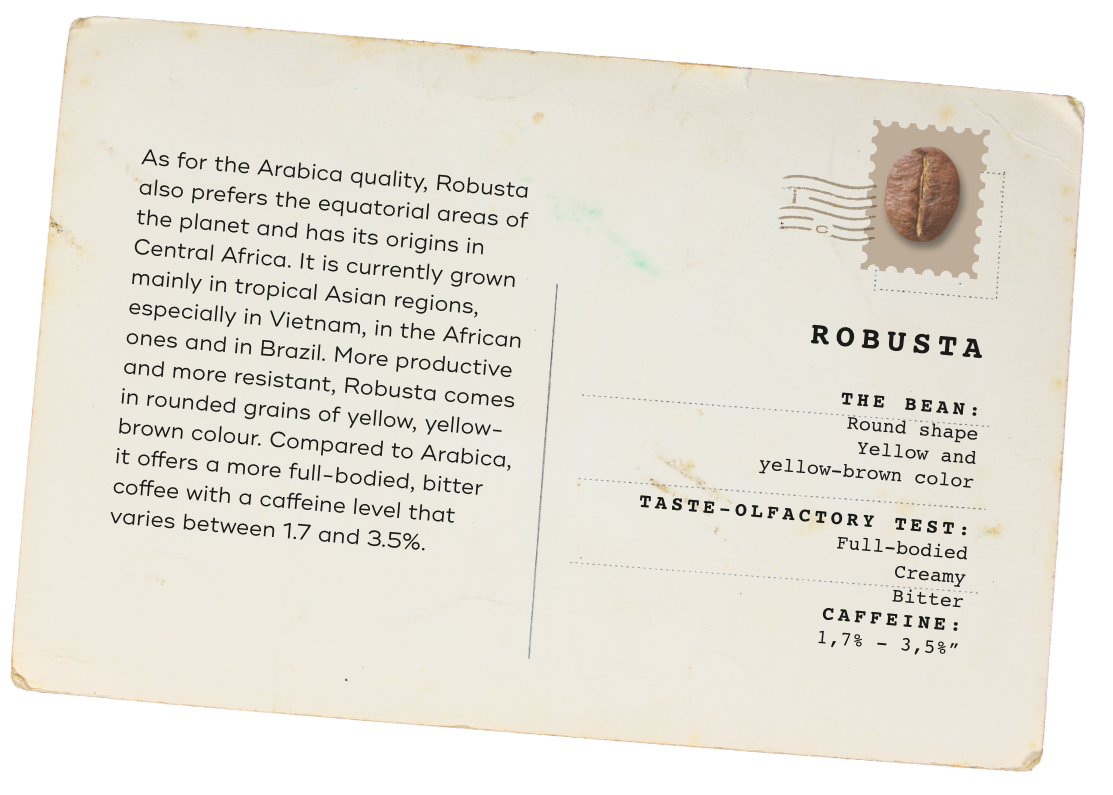

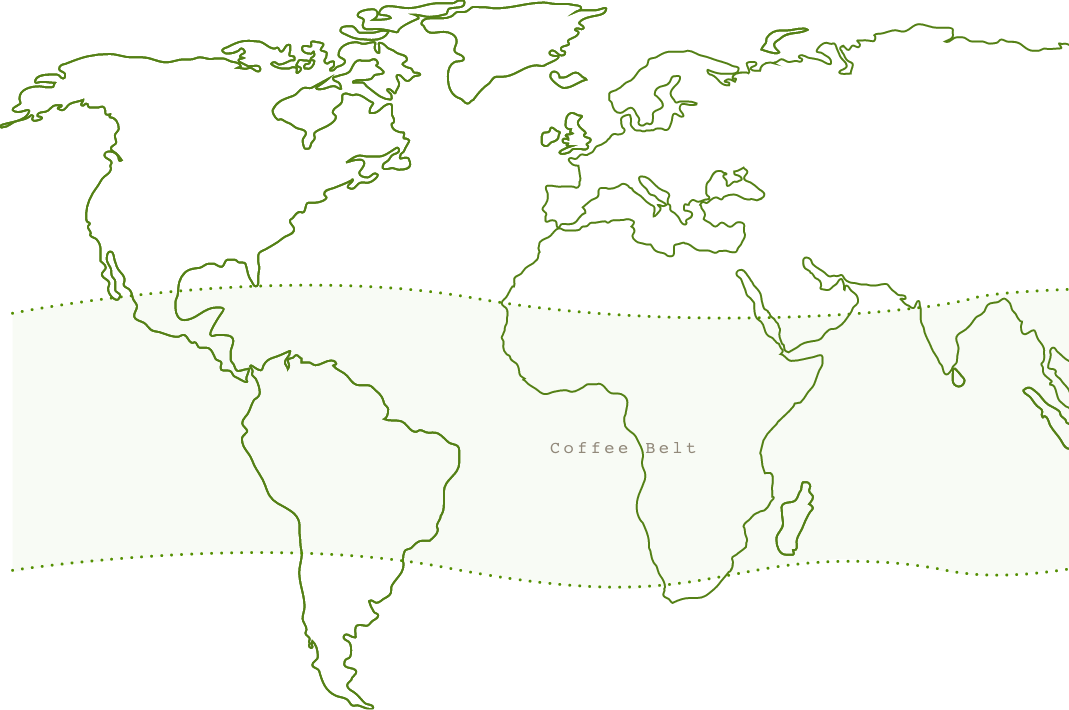

The main area of growing for coffee plantations is the so-called "coffee belt" and extends between the tropics of Cancer and Capricorn.

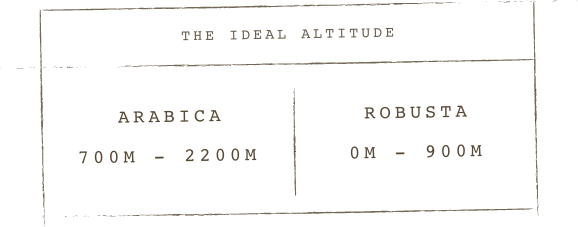

This band of the planet is the most suitable for the growing of this delicate plant because the average temperature varies between 18 and 24°C, thus limiting any possible risk of frost or extreme heat. Another very important element for the development of the plant is the altitude: the Arabica quality grows at an altitude between 700 and 2200 meters, while the Robusta grows between 0 and 900 meters.

The main area of growing for coffee plantations is the so-called "coffee belt" and extends between the tropics of Cancer and Capricorn.

This band of the planet is the most suitable for the growing of this delicate plant because the average temperature varies between 18 and 24°C, thus limiting any possible risk of frost or extreme heat. Another very important element for the development of the plant is the altitude: the Arabica quality grows at an altitude between 700 and 2200 meters, while the Robusta grows between 0 and 900 meters.

The coffee

The coffee plant is an evergreen shrub belonging to the Rubiaceae family of the coffea genus, with dark and pointed shiny green leaves and a white inflorescence resembling, in shape and intense fragrance, those of jasmine. The fruits, green and cherry-shaped, change their colour to red when they reach full maturity. Inside each drupe there are two grains, flat in contact, separated by a groove and convex on the outside. In some cases, when the fruit grows at the end of the branch, a single round bean can develop inside the drupe, which is called a “Caracolito” or coffee pearl.

The three "original" moments

The goodness of coffee, from the beginning

A great journey...

Up to Trieste, the Port of Europe

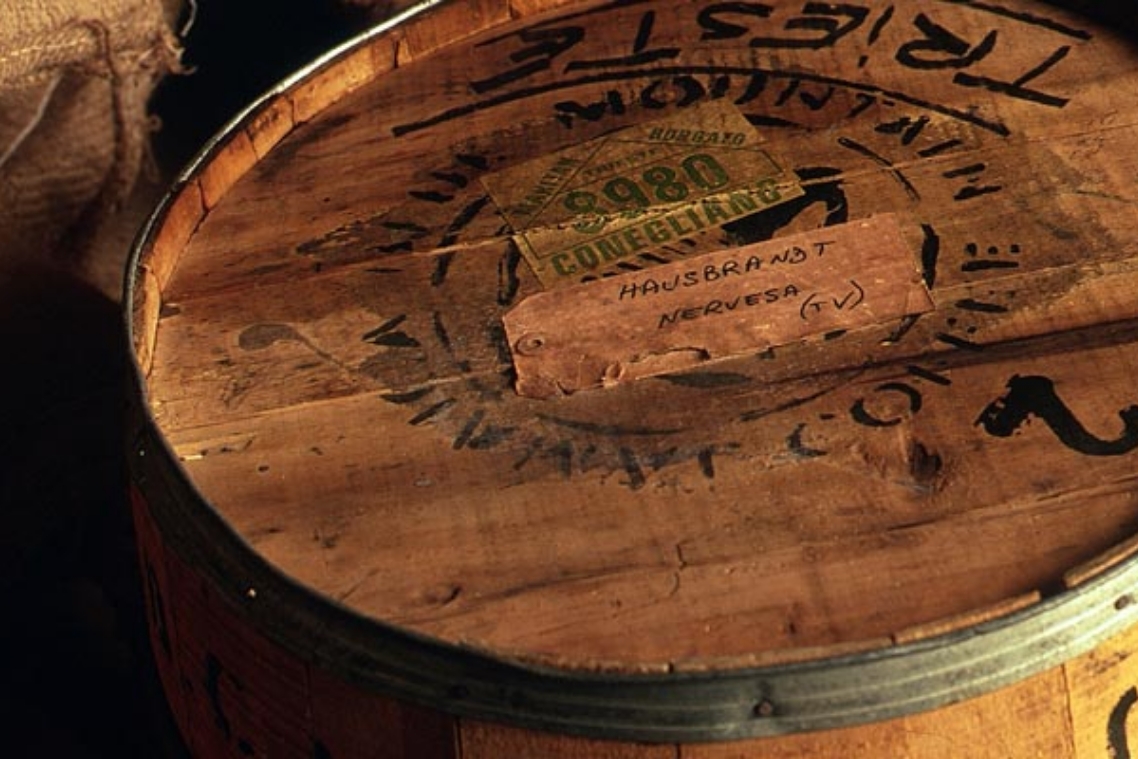

Trieste is called the "Capital of Coffee" and for over two centuries has been one of the main European ports for the import of beans from tropical countries.

It is precisely here that the second "macro phase" of coffee bean selection takes place to check that the quality and organoleptic properties have not undergone alterations during the great sea journey. Even today, thanks above all to the work of Virginio Zanetti, through a widespread logistics structure and the constant availability of product in its warehouses in the port of Trieste, Hausbrandt coffee arrives in our factories in Nervesa della Battaglia, in the province of Treviso for the subsequent stages of selection and roasting of coffee beans.

The roasting

Home of science and quality

The long manufacturing process necessary to obtain a perfect cup of espresso coffee forces Hausbrandt to constantly monitor all the individual production phases. These countless steps, checks, examinations and tests are essential steps to guarantee the customer a perfect product, which as such expresses his entire personality in the cup.

The beginning of creation

The mixture

At Hausbrandt, for over a hundred years, tradition and experience have been complemented by knowledge and technological innovation to create a deep and authentic culture of good coffee. The perfect combinations of single origins and the different dosages of Arabica and Robusta quality create the right blends capable of offering fullness of taste, fragrance of aroma and roundness of the body, that are the essential elements for an excellent coffee. The secret of Hausbrandt Trieste 1892 blends is certainly their composition. For example, the Gourmet Columbus blend hides the secret of a unique recipe adjusting a precious combination of bitter cocoa and liquorice root hints. Harmonious, full and refined taste thanks to the careful selection of the best qualities of Colombian Arabica.

The moment of quality

Slow roasting

Hausbrandt uses a method called "slow roasting", during which a temperature of 210° C is reached. In this phase, which lasts from 15 to 16 minutes, the time necessary to obtain a coffee with a uniform colour that keeps all the aromas and organoleptic properties intact, the heat curve is constantly monitored, thanks to specific thermal probes. At the end of the roasting process, the beans are immediately cooled in order to block their natural self-combustion process.

The time of constancy

The right rest

Once roasted, coffee needs a rest period in which it fully develops its qualities. After a few days of rest, it is vacuum packed, in jars or bags, suitable for perfectly preserving the product.

Cultivation

A delicate care

An excellent cup of coffee is the result of a long and careful work that starts from the very first stages of the plant's growth. It takes about 3 or 4 years for the plant to become productive. The small shoots, after being planted in deep, permeable and neutral or slightly acidic soils, are subjected to constant careful and intense care.

Harvesting

A careful collection

There are two harvesting systems: picking and stripping. The first, completely manual, consists of harvesting only the red cherries from the coffee plant and therefore fully ripe. It is certainly a very expensive method, but it guarantees a decidedly high average quality of the product. Stripping, on the other hand, consists of a much quicker operation which shells the entire bunches that have reached maturity by hand, or with special machines. Once on the ground, the grains are collected and placed in the baskets, but with this system the risk of recovering even unripe or overripe grains increases compared to the first method. Once harvested, the beans are separated from the pulp either dry or wet. The dry method is what makes it possible to obtain "natural" coffees and consists of drying cherries in the sun for several days. After the time necessary for complete drying, the drupes are peeled using special machinery, thus removing the peel and dry pulp. The wet method, which is much more expensive, allows to obtain so-called "washed" coffees. The drupes are processed using machinery to remove the pulp to extract the parchment. Subsequently, parchment is placed inside fermentation tanks. At the end of this process, it will be washed and dried mechanically or in the sun. Once dried, the seeds will be passed to the peeling machine which will remove the parchment and release the green grain.

Selection

A precise choice

The quality of the coffee is the main distinctive element of Hausbrandt and that is why high checking and control systems are adopted. In fact, there are many interventions aimed at guaranteeing the highest levels of quality and a dedicated team of Hausbrandt technicians is constantly committed to monitoring every single phase of the selection, so that only the best coffees reach the roasting stage in optimal conditions.

Perché Trieste

History

Following the death of Charles VI, the young Maria Theresa of Habsburg succeeded to the throne who, thanks to a careful economic policy, allowed Trieste to become one of the main ports of Europe. Since the 14th century, under the protection of the Duke of Austria, Trieste retained a certain autonomy until 1719, when Charles VI of Austria appointed Triste as free port, thus transforming it into one of the main outlets to the Mediterranean of the Austrian Empire. The importation of coffee immediately became one of the main features of the port of Trieste so much so that, as early as 1748, the first coffee shop opened in the city.

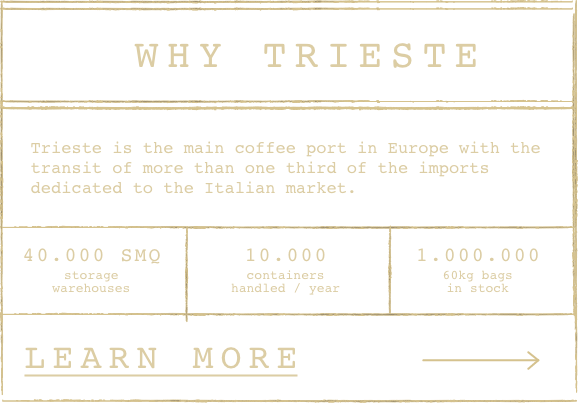

The port

Trieste is one of the main coffee ports in Europe, with the transit of more than 20% of imports dedicated to the Italian market. Figures: 40.000 sqm / warehouses storage 10.000 containers handled / year 1.000.000 bags of 60 kg in stock

The commodity chemical laboratory

Trieste is the headquarters of the Commodity Chemical Laboratory of the Trieste Chamber of Commerce. It is the only place in Italy where the absolute ability to "qualify" a coffee is recognized and on behalf of the Ministry of Health, this centre performs technical and study functions related to the health and hygiene discipline of the production and trade of coffee products.